Quality, Integrity, Knowledge, and Service is what we offer!

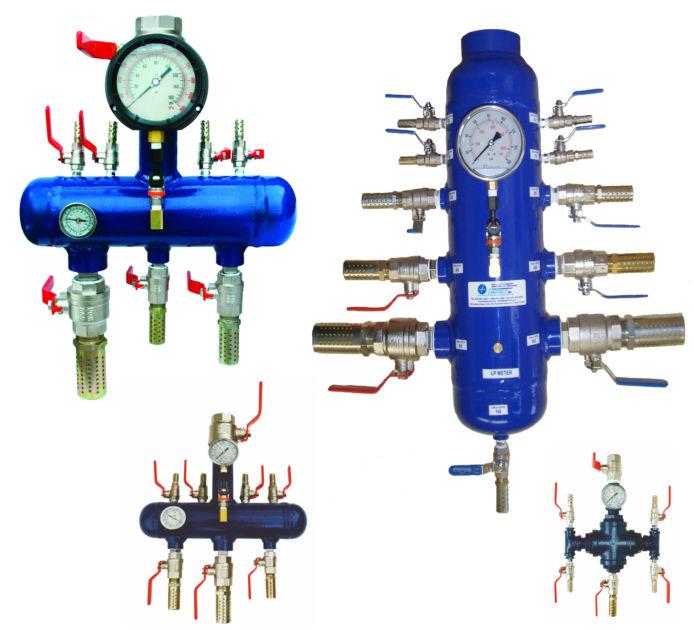

LP Flow Meters

The LP Flow Meter enables one to perform compressor capacity tests on all types of compressors. When testing one can verify the CFM (Cubic Feet per Minute) of FAD (Free Air Delivery) output of a compressor within 2% accuracy and determine if the unit is performing to original manufacturer’s specifications.

Premature modulation

Are your compressors delivering the output they are rated for? Problems with modulating controls which choke the air inlet prematurely on rotary screw compressors can also be detected on Ingersoll - Rand, Gardner Denver, Quincy, CompAir, Sullair and other well known models.

Plant air leakage

Additional savings in the thousands of dollars can be achieved through leak measurement. Use the LP Meter to quantify your air leaks in the piping network.

LP07

| Single compressor capacity (CFM): | Maximum 1600 CFM |

| Single compressor capacity (HP): | Maximum 400 HP |

| Dimensions: | W - 17.5'' L - 28.5'' D - 13.5'' |

| Test range: | 10 - 1600 CFM |

| Connection: | 2'' NPT(F) |

| Weight: | 45 LBS |

Whether determining the performance of a rotary screw compressor or a reciprocating compressor, the LP range of flow meters can provide you with the information necessary to determine maintenance adjustments or overhauls.

Easy to install and operate; it takes minutes to perform a compressor capacity test, an air leak test or a production consumption test.

Standard Features:

- Precision to within 2% accuracy

- ASME Coded and stamped

- CRN Approved

- Stainless steel orifices

- Liquid filled precision gauge

- Rugged direct mounted thermometer

- Diffused exhaust ports for additional safety

- Custom units are available in Stainless Steel

The LP07 Flow Meter enables one to perform compressor capacity tests on all types of compressors. When testing one can verify the CFM (Cubic Feet per Minute) of FAD (Free Air Delivery) output of a compressor within 2% accuracy and determine if the unit is performing to original manufacturer’s specifications.

Premature modulation

Are your compressors delivering the output they are rated for? Problems with modulating controls which choke the air inlet prematurely on rotary screw compressors can also be detected on Ingersoll - Rand, Gardner Denver, Quincy, CompAir, Sullair and other well known models.

Plant air leakage

Additional savings in the thousands of dollars can be achieved through leak measurement. Use the LP Meter to quantify your air leaks in the piping network.

LP150

| Single compressor capacity (CFM): | Maximum 800 CFM |

| Single compressor capacity (HP): | Maximum 200 HP |

| Test range: | 10 - 800 CFM |

| Connection: | 1 1/2'' NPT(F) |

| Dimensions: | W - 15.75'' x L- 25'' x D - 6'' |

| Weight: | 26 LBS |

Whether determining the performance of a rotary screw compressor or a reciprocating compressor, the LP range of flow meters can provide you with the information necessary to determine maintenance adjustments or overhauls.

Easy to install and operate; it takes minutes to perform a compressor capacity test, an air leak test or a production consumption test.

Standard Features:

- Precision to within 2% accuracy

- ASME Coded and stamped

- CRN Approved

- Stainless steel orifices

- Liquid filled precision gauge

- Rugged direct mounted thermometer

- Diffused exhaust ports for additional safety

- Custom units are available in Stainless Steel

The LP150 Flow Meter enables one to perform compressor capacity tests on all types of compressors. When testing one can verify the CFM (Cubic Feet per Minute) of FAD (Free Air Delivery) output of a compressor within 2% accuracy and determine if the unit is performing to original manufacturer’s specifications.

Premature modulation

Are your compressors delivering the output they are rated for? Problems with modulating controls which choke the air inlet prematurely on rotary screw compressors can also be detected on Ingersoll - Rand, Gardner Denver, Quincy, CompAir, Sullair and other well known models.

Plant air leakage

Additional savings in the thousands of dollars can be achieved through leak measurement. Use the LP Meter to quantify your air leaks in the piping network.

LP3000

| Test range: | 10 - 3000 CFM |

| Connection: | 3'' NPT(F) |

| Single compressor capacity (CFM): | Maximum 3000 CFM |

| Dimensions: | W - 26.25'' L - 30.25'' D - 9.0'' |

| Single compressor capacity (HP): | Maximum 750 HP |

| Weight: | 80 LBS |

Whether determining the performance of a rotary screw compressor or a reciprocating compressor, the LP range of flow meters can provide you with the information necessary to determine maintenance adjustments or overhauls.

Easy to install and operate; it takes minutes to perform a compressor capacity test, an air leak test or a production consumption test.

Standard Features:

- Precision to within 2% accuracy

- ASME Coded and stamped

- CRN Approved

- Stainless steel orifices

- Liquid filled precision gauge

- Rugged direct mounted thermometer

- Diffused exhaust ports for additional safety

- Custom units are available in Stainless Steel

The LP3000 Flow Meter enables one to perform compressor capacity tests on all types of compressors. When testing one can verify the CFM (Cubic Feet per Minute) of FAD (Free Air Delivery) output of a compressor within 2% accuracy and determine if the unit is performing to original manufacturer’s specifications.

Premature modulation

Are your compressors delivering the output they are rated for? Problems with modulating controls which choke the air inlet prematurely on rotary screw compressors can also be detected on Ingersoll - Rand, Gardner Denver, Quincy, CompAir, Sullair and other well known models.

Plant air leakage

Additional savings in the thousands of dollars can be achieved through leak measurement. Use the LP Meter to quantify your air leaks in the piping network.

LP50

| Single compressor capacity (CFM): | Maximum 200 CFM |

| Single compressor capacity (HP): | Maximum 50 HP |

| Test range: | 10 - 200 CFM |

| Connection: | 1'' NPT(F) |

| Dimensions: | W - 13'' x L - 21'' x D - 4.5'' |

| Weight: | 15 LBS |

Whether determining the performance of a rotary screw compressor or a reciprocating compressor, the LP range of flow meters can provide you with the information necessary to determine maintenance adjustments or overhauls.

Easy to install and operate; it takes minutes to perform a compressor capacity test, an air leak test or a production consumption test.

Standard Features:

- Precision to within 2% accuracy

- Stainless steel orifices

- Liquid filled precision gauge

- Diffused exhaust ports for additional safety

- Custom units are available in Stainless Steel

The LP50 Flow Meter enables one to perform compressor capacity tests on all types of compressors. When testing one can verify the CFM (Cubic Feet per Minute) of FAD (Free Air Delivery) output of a compressor within 2% accuracy and determine if the unit is performing to original manufacturer’s specifications.

Premature modulation

Are your compressors delivering the output they are rated for? Problems with modulating controls which choke the air inlet prematurely on rotary screw compressors can also be detected on Ingersoll - Rand, Gardner Denver, Quincy, CompAir, Sullair and other well known models.

Plant air leakage

Additional savings in the thousands of dollars can be achieved through leak measurement. Use the LP Meter to quantify your air leaks in the piping network.